Getting Started

Jump to:

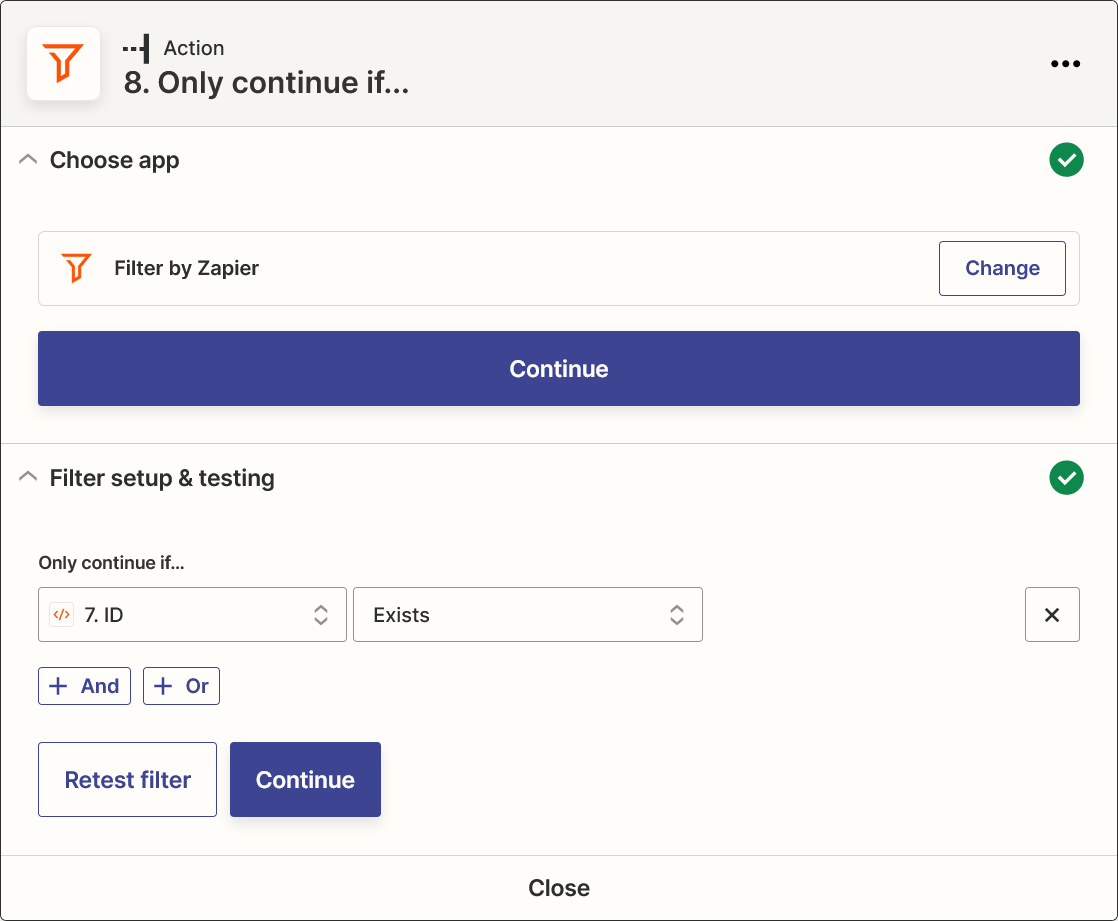

Quick start guide

Jump to:

- Overview of MRPeasy.

- Play with demo data.

- Remove demo data and prepare a test task.

- Enter parts and products.

- Plan and report production.

- Buy parts and materials.

- Sell products.

- Stock management.

- Usage tips.

Overview of MRPeasy

MRPeasy is suitable for both make-to-stock and make-to-order production modes.

The program is divided into eight main sections:

- CRM - sales and order management.

- Production planning - production planning and management.

- Stock - inventory management.

- Procurement - purchasing management.

- Dashboard - quick overview of main indicators.

- My production plan and Internet-kiosk - real-time reporting of manufacturing operations by the worker.

- Settings - your MRPeasy settings, account management, user management, and database maintenance.

- Accounting - standard accounting module.

General usage flowchart:

Play with demo data

- Play with the demo data already present in the system to get a quick overview.

- You can explore three different demo datasets, which you can load from the Demo data and videos section.

- The initial dataset is the simplest. The demo company produces a simple product, a Wooden Table:

- It is made of legs, a top, and varnish. These are separate items with vendors, lead times, and prices.

- It is produced in two steps: Assembly and Painting. Both have an associated workstation, designated duration, and costs.

- Try to buy some parts with a Purchase Order.

- Try to make some tables with a Manufacturing Order.

- Try to sell some tables with a Customer Order.

- You can clean up and re-upload fresh demo data in the Demo data and videos section.

- Watch the demonstration videos.

- Follow the Testing manual.

Prepare a test task

Once you are ready to start testing with your own data:

- Empty the database from demo data, at Settings -> Database maintenance.

- Add other users who will test the system, at Settings -> Human resources.

- Enter a simple test task.

- A simplified product with a few materials and operations will be perfect.

- Define the outcomes that you wish to accomplish with each test task.

- Read and apply the MRPEASY IMPLEMENTATION GUIDELINES.

- Follow the examples in the Testing manual.

- A simplified product with a few materials and operations will be perfect.

Enter your parts and products

At Stock -> Items, you should enter your items in the following order:

- The parts and materials you buy.

- For procured items, add the Purchase Terms to define the vendor(s), cost, and lead time.

- The products you make.

- For manufactured items, add a Bill of Materials (BOM) and a Routing.

See also:

- Demo videos:

- User Manual: Item details.

Plan and report production

At Production planning -> Manufacturing orders, you can create new Manufacturing Orders (MO) to make the products.

- You can report the progress and usage of materials from stock by pressing Go to production inside the MO.

- Products are counted into stock once the MO is finished.

- You can add new users and give them rights to My Production Plan or the Internet kiosk so your colleagues can log in and report production in real time.

See also:

- Demo videos:

- User Manual:

Make-to-stock (MTS) manufacturing

In the make-to-stock manufacturing mode, the manufacturing is planned before customer orders arrive.

For making to stock, there are several ways of creating Manufacturing Orders (MOs):

- Add a new MO at Production planning -> Manufacturing orders.

- Assign a Reorder Point (ROP) for each item, even 0, and use the Stock -> Critical on-hand report to create MOs for items that are below their reorder point.

- Create MOs from the Procurement -> Forecasting function.

Make-to-order (MTO) manufacturing

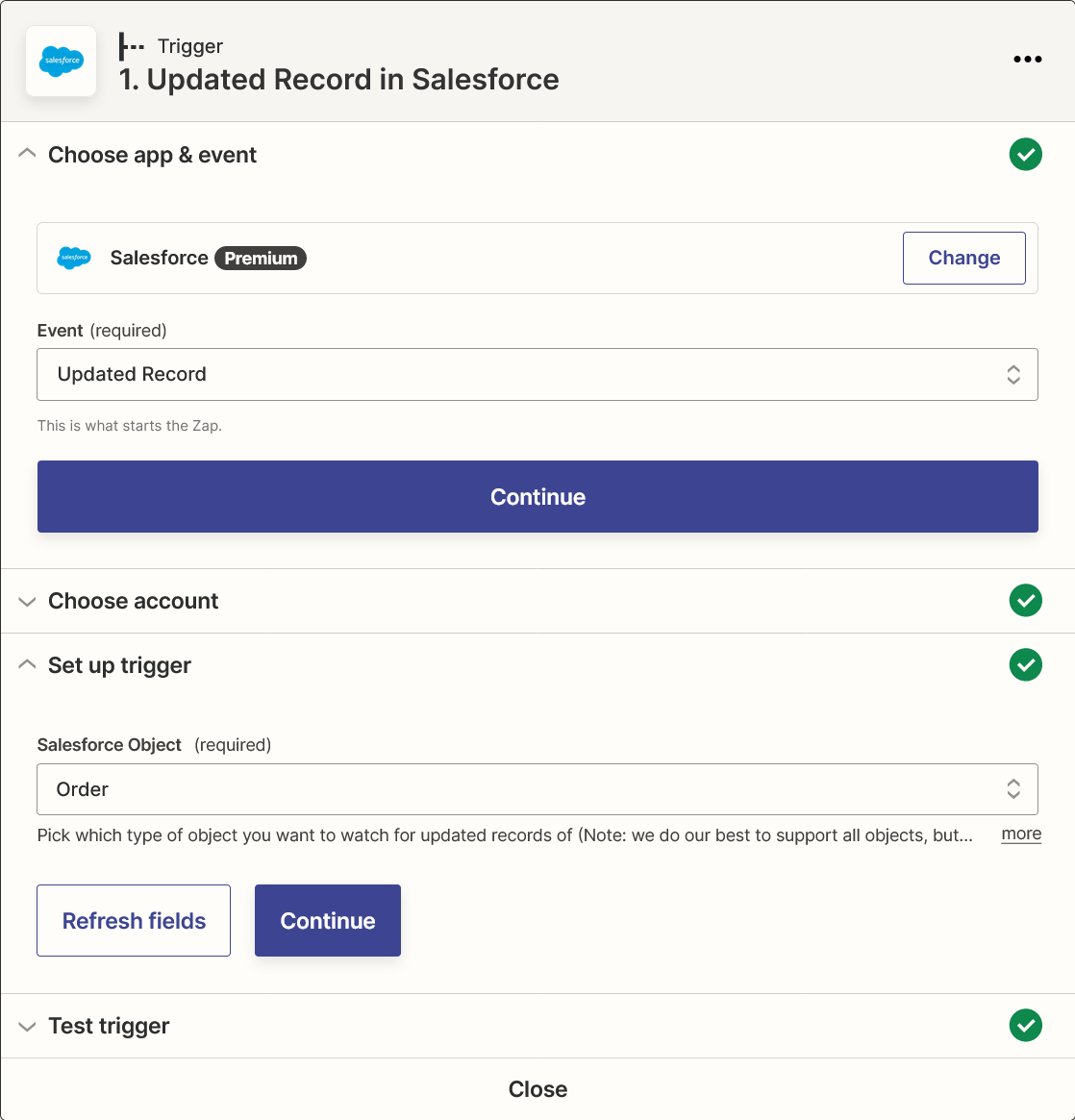

In the make-to-order manufacturing mode, the basis of production planning is a sales order, a "Customer Order" (CO) in MRPeasy.

- Add a new CO at CRM -> Customer Orders.

- After saving it, you can estimate costs and delivery dates.

- When you are ready to start planning production, you can:

- Automatically generate one MO per one CO line.

- Create one MO for several COs (i.e., the same product, different orders).

- Manually create a Manufacturing Order (MO) and book it to the CO.

Buy parts and materials

At Procurement -> Purchase Orders, you can create Purchase Orders (PO) to order items from your vendors.

Mark the PO as received to take the ordered items into stock.

See also:

- Demo video: Purchasing Management.

- User manual: Purchase Order details.

Low inventory alerts

There are two reports that show what needs to be ordered and which help to easily raise necessary Purchase Orders:

- Procurement -> Requirements.

- A list of items missing in specific sales and manufacturing orders.

- Procurement -> Procurement Critical on-hand.

- A list of items for which availability is below their Reorder point (ROP).

These reports are automatically generated based on the information from stock, customer orders, and manufacturing orders.

- If parts are missing for an MO, demand is raised automatically.

- If products are missing for a CO, demand is raised for them after you try booking them.

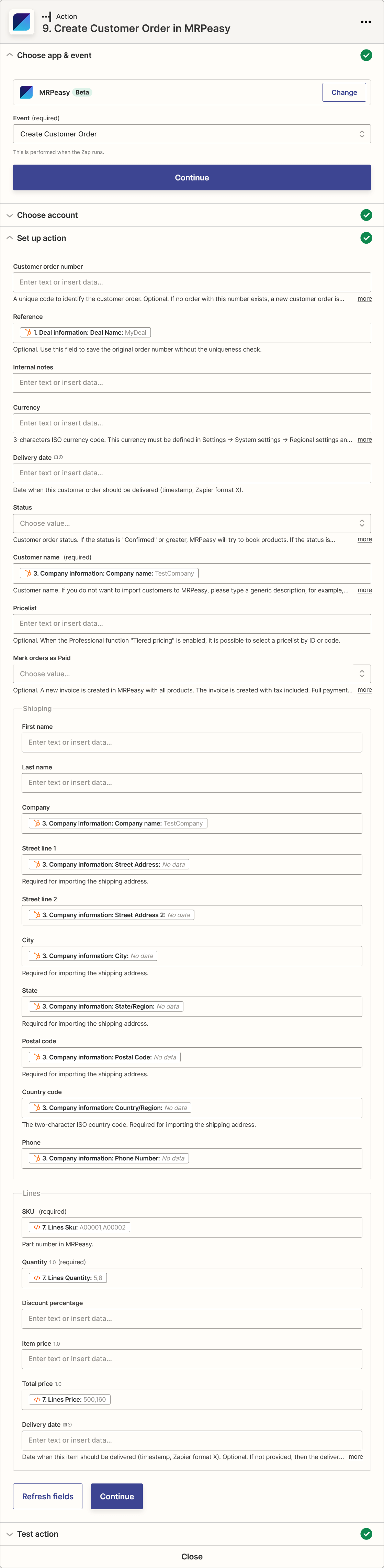

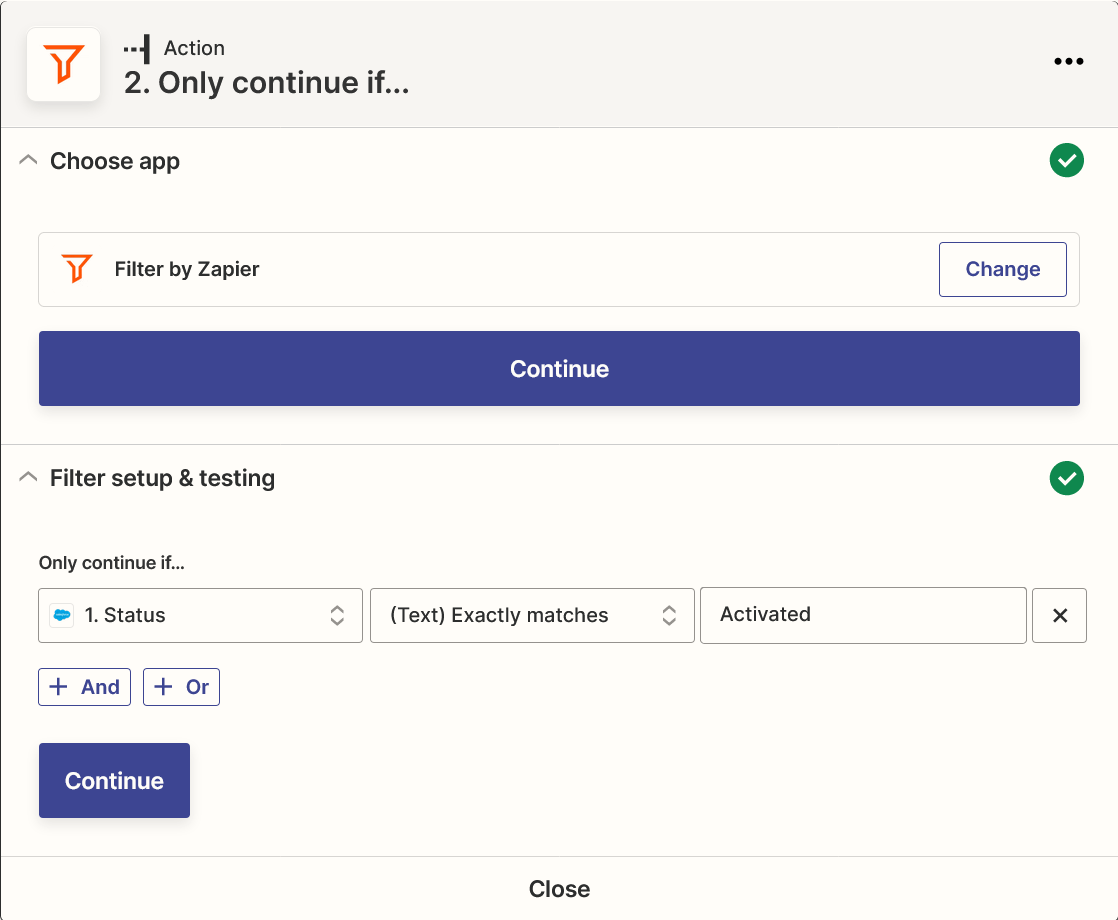

Sell products

At CRM -> Customer Orders, you can create new Customer Orders (CO) to enter new sales orders.

The CO is the core document for tracking the sale from quotation to delivery, including issuing documents such as order confirmations, invoices, and waybills and tracking payments.

- Create quotations, order confirmations, or invoices.

- Estimate costs and dates.

- Book products for the CO.

- Booking means reserving some specific items for this order.

- These items could be in stock right now, or they could still be planned (e.g., reserved from a future PO or MO).

- If items are unavailable, demand will be created for the products.

- Create a Shipment and a waybill, and pick the products to take them off stock.

See also:

- Demo videos:

- User Manual: Customer Order details.

If you make to order, the process of handling the order could look like the one below.

Stock management

The Stock -> Items provides a detailed overview of your stock. It distinguishes between:

- In stock vs Expected (coming in the future) quantities.

- Available vs Booked (reserved for something) quantities.

Inventory transactions are automatically made when users in different roles (e.g., sales, production, procurement) report what they've done.

See also:

- Demo videos:

- User manual:

Basic principles of inventory management in MRPeasy

- Before items can be used for something, they must be booked first.

- The method of inventory management is "stock lot tracking."

- You could label your items with stock lot labels to keep track of batches.

- Enjoy detailed Stock Movement reports.

Complete User Manual

The User Manual can be found here:

A one-page online version of the User Manual:

If you wish to have the complete User Manual in PDF format, print a one-page version and choose Print as PDF.

Usage tips

Jump to:

- Demo video: Usage tips.

- Buttons and icons.

- Quick help.

- Data tables.

- Search wildcards and operators.

- Browser security settings.

- Miscellaneous.

Buttons and icons

- Add Add a new entry

- Edit Edit/View an existing entry

- Bulk editing Bulk editing

- Choose columns Choose columns to be displayed

- Search Search by specified conditions

- Saved searches Saved searches - each user can save personal filters. Saved searches store selected columns, their order, and filled parameters. A saved search can also be set as the default, making it automatically applied.

- Reports View reports

- Important notice Important notice

- Actions View action log

- Rebook materials Rebook materials for planned Manufacturing Orders (Production schedule)

- Press and drag up or down to change order Drag up or down

- Create a Purchase Order Create a Purchase order (Procurement Critical on-hand, Requirements)

- Consume Consume item (MO details for worker)

- Pick Pick item (Shipment)

- Create a manufacturing order Create a Manufacturing order (Critical on-hand in Stock)

- Return item to stock Return item to stock

- Print barcode Print barcode

- Start Start the production operation

- Pause Pause the production operation

- Stop Finish the production operation

- Show images Show images

- Move Move window

- Quick help Quick help

- Tasks Tasks

- Page navigation Page navigation

- List or detailed view List or detailed view

- Sales pipeline view Sales pipeline view

- View sums View sums

- Users Sign in for more users at the internet-kiosk device

- User Switch between users or sign out from internet-kiosk

Quick help

If you need an explanation for any page throughout the program, click on the Quick help button in the top right-hand corner.

Data tables

- Tables can be sorted by clicking on column titles.

- The order of columns can be arranged by clicking, holding, and dragging their titles.

- In many tables, clicking on the "Choose columns" button allows you to show additional columns or hide unneeded ones.

- The table layouts are remembered for each user separately.

- If the list of items contains more than 20 elements, the software displays only the first 20 items by default. Click Load more to load the rest of the list.

- In drop-down menus such as Status, it is possible to select multiple options while holding the Ctrl key.

Search wildcards and operators

There are several wildcards and operators, that can be used when searching:

- _ can be used as a placeholder (wildcard) for any symbol.

- "w__d" finds all results with exactly two symbols between "w" and "d," e.g., "wood."

- % can be used as a placeholder (wildcard) for multiple symbols.

- "w%d" finds all results that have any number of symbols between "w" and "d," e.g., "wood" and "washed."

- && ignores the order of words.

- "wood && table" finds both "wooden table" and "table from wood."

- || finds data containing at least one word when searching by text.

- "wood || table" finds both "wooden chair" and "plastic table."

- - (minus) finds data that does not contain certain words.

- "-plastic" excludes "plastic" from the results.

- "table && -plastic" finds all data for "table" except for those containing "plastic."

- "-" is a negative operator only when it is the first character or if it is following a space.

- If your data starts with "-" or has a suffix added with "-" according to which you wish to search, e.g., "-ABC," then please use "%-abc" to find the data.

- "" (double quotation marks) finds rows without data in that column.

- -"" finds non-blank lines.

- Several conditions may apply together. They can be grouped and prioritized using parentheses.

- "table && -(plastic || white)" finds all tables which are neither plastic nor white.

Browser security settings

MRPeasy is internet-based software that works in a browser. Please check your browser privacy settings: cookies, JavaScript (scripting), and website data must be allowed (at least "Allow from Current Website Only").

Miscellaneous

- Tooltips are provided for all fields throughout the program. If a field is not understandable, simply move your mouse over its title.

- MRPeasy is only accessible online; it is not downloadable software.

- Sometimes, the system seems to malfunction when the user uses multiple browser tabs or windows simultaneously. This is not recommended.

Supported Languages

MRPeasy is designed for global manufacturers. To ensure a seamless user experience across borders, the software interface is available in multiple languages.

You can select your preferred language during sign-in or from the Start page by clicking the globe icon in the top-right corner.

Please note that while the MRPeasy interface is available in multiple languages, customer support is currently provided in English only.

We are continuously working to improve the quality and accuracy of our localizations. If you notice any issues or have suggestions for improvement, we warmly welcome your feedback. Please don’t hesitate to contact our support team.

Available interface languages

Below is the full list of currently supported languages in MRPeasy:

- Chinese (simplified) - 简体中文

- Chinese (traditional) - 繁體中文

- Czech - Čeština

- Danish - Dansk

- Dutch - Nederlands

- English

- Estonian - Eesti

- Finnish - Suomi

- French - Français

- German - Deutsch

- Hungarian - Magyar

- Indonesian - Bahasa Indonesia

- Italian - Italiano

- Latvian - Latviešu

- Lithuanian - Lietuvių

- Norwegian - Norsk

- Polish - Polski

- Portuguese - Português

- Russian - Русский

- Slovak - Slovenčina

- Slovenian - Slovenščina

- Spanish - Español

- Swedish - Svenska

- Turkish - Türkçe

System Requirements

MRPeasy is a cloud-based AI-powered self-service ERP/MRP software for small manufacturers (10-200 employees).

Cloud-based means that users access the software via their browsers.

We support the main browsers, like Microsoft Edge, Google Chrome, Safari, and Mozilla Firefox.

It is always better to have the newest version of the browser; you can check which version is the newest in the respective browsers.

We update our mobile applications for iPhones and Android devices ourselves, but it is recommended that you have the newest version of iOS or Android.

As of April 2024, the latest version of iOS is iOS 16, and the newest version of Android is Android 15.1.

Demo Data and Videos

In the software section Demo data and videos you can watch demo videos, upload demo data, and clear the database.

Jump to:

- Watch the first demo video - get 5 free days.

- All demonstration videos.

- Upload demo data.

- How to delete the demo data and clear the database.

Watch the demonstration video and get 5 FREE days

We have a short video that describes how MRPeasy generally works. Watching this will also give you 5 free days.

In addition, there are many training videos available on every topic. If you are new or had a pause in working with MRPeasy, these are great learning tools and memory refreshers.

Uploading demo data

You can explore three different demo datasets by adding them to your database.

Their purpose is to demonstrate the general functionalities and structure of MRPeasy without first requiring data entry from you and provide you with blueprints for conducting your own testing.

Take note:

- Empty your database before adding another demo dataset to your data. Or before you start entering your own data. This helps to avoid any confusion or a mess that could be difficult to clean up later.

- The datasets are added to the existing data in your database.

- You should not add demo data once you are operating with actual data.

Simple discrete manufacturing

The first dataset is a setup example of simple discrete manufacturing of assembling and painting wooden tables.

Understanding this simplistic dataset is a good starting point for your MRPeasy journey, as the same foundational principles apply to all industries, from building tables to producing airplanes.

Complex discrete manufacturing

Do you manufacture more complex products? You can also add demo data suitable for studying multi-level BOMs and multi-level Manufacturing Orders.

This demo dataset is recommended for discrete manufacturing, particularly in the Electronics, High Tech, Industrial Equipment, and similar industries.

Process manufacturing

Are you producing food or in similar industries? If so, add the demo data focused on process manufacturing. This dataset is an example of ice cream production.

This is a useful blueprint, especially for those in the Food and Agriculture, Pharmaceutical, Health, and Beauty industries or related sectors.

How to delete the demo data and clear the database

There are two options for emptying the database:

- Click the Empty the database button to delete all data (except users and settings).

- Click the Delete all orders and stock button to delete all orders (MO, CO, PO, RMA, SO) and inventory levels only.

The so-called seed or master data will remain - customers, vendors, articles, BOMs, Routings, Workstations, etc.

Database Maintenance

Under Settings -> Database maintenance it is possible to:

- Download a database backup.

- Restore a database backup.

- Archive old data.

- Partially clear or fully empty the database.

- Required user access rights.

Database backup and restoration

You can download your database backup file to your computer and keep a copy. It is advised that you do this at least once a month.

You can upload the database backup file to restore your data. The valid backup file is the following:

- The file is not older than 30 days.

- It is downloaded from the same account it is restored to (it is impossible to upload a backup file from one account to another).

- It is not edited in any way.

Your current database will be erased during upload and replaced with the data from the backup file. You are advised to download a new backup file before uploading an older backup.

All users will be signed out during the restoration.

Attention! The MRPeasy database backup file can be used/read in the MRPeasy only. Please do not try to open and edit it in other programs.

Archiving old data

It is possible to archive older data, which has not been used for the last 6 months, 1, 1.5, or 2 years in bulk at Settings -> Database Maintenance -> Archive old data.

Archived objects are not deleted completely. These are normally hidden but can be found at any time.

The following objects are archived:

- Items, bills of materials, and routings.

- Customer Orders, Purchase Orders, Manufacturing Orders, Service Orders, and RMA Orders.

1. Archiving items, bills of materials, and routings

Those goods that have not been used for a given period and are not in stock can be archived. Stock items are archived along with their bills of materials and routings. BOMs and routings that belong to archived products are also archived.

Archived:

- Items can be found at Stock -> Items by searching for the part number.

- BOMs can be found at Production planning -> BOM by searching for the BOM number.

- Routings can be found at Production planning -> Routings by searching for the routing number.

Archived items, BOMs, and routings can be restored:

- Find it.

- Open it.

- Click the Restore button.

2. Archiving orders

The following orders are archived:

- Customer orders: in statuses Shipped and Delivered.

- Purchase orders: in status Received.

- Manufacturing orders: in statuses Done, Shipped, and Closed.

- Service orders: in status Done, Shipped, and Closed.

- RMA orders: in statuses Shipped and Delivered.

Archived orders get the status Archived.

Objects with the status Archived aren’t shown in the general list.

Emptying the database

There are two options for emptying the database:

- Empty the database

- Delete all data (except users, settings, and sites).

- Numbering formats will be reset. - Delete orders and stock

- Delete all orders (MO, CO, PO, RMA, SO) and inventory levels.

- The so-called seed or master data will remain - items, customers, vendors, BOMs, routings, workstations, etc.

- Numbering formats will not be reset.

It is advised to download a new backup file before any deletion!

User access rights for database operations

Required user access rights:

- To download a database backup the user must have Read right for the Settings -> Database maintenance section.

- To restore a database backup, archive data, or empty the database, the user must have Read and Update rights for the Settings -> Database maintenance section.

Account and Billing

You can see and manage the state of your account at Settings -> Account and billing.

Here you can:

- See the paid until date, the number of users, and the next invoice amount.

- Order MRPeasy.

- See and pay invoices.

- Change your pricing plan.

- Downgrade your account.

- Pay for more users.

- Change the billing cycle.

- Change the account's company name, contact e-mail, and billing e-mail.

- Stop billing.

- Delete your account.

How to order MRPeasy

Note that you will not be charged during the free trial period or for the free trial.

At the end of the free trial, a proforma invoice will automatically be issued for the next billing period. Once it is paid, you can continue using MRPeasy.

To order MRPeasy:

- Follow the instructions, which you will receive in your email after the end of the trial.

- Or go to Settings -> Account and Billing -> Invoices, open the Invoice, and proceed to checkout.

- If you wish to continue with automatic renewal, choose to save the card or PayPal details for the next payments.

After the proforma invoice is paid, a tax invoice is automatically generated and can be found in Settings -> Account and Billing -> Invoices.

You can also enter and change payment details anytime at Settings -> Account and billing -> Payment data.

You can define a separate billing email address to which invoices will be delivered.

How to pay your invoices

You can see your invoices at Settings -> Account and billing -> Invoices.

All invoices are displayed here:

- invoices for the MRPeasy subscription;

- plus additional invoices, e.g., for adding new users, upgrading, or ordering training.

To pay an unpaid invoice, open it and proceed to checkout.

How to add more users to the subscription

To add more users to the subscription:

- Go to Settings -> Human Resources and press the "+" button. Then, you can choose how many users you'd like to add.

- The software will automatically generate a proforma invoice, which is proportional to the time until the end of the current billing cycle.

- The amount of the invoice = (pricing plan price) X (number of new licenses) X (days until the end of the current billing cycle) / (365 or 30, depending on the billing cycle).

- Once you have 10 users, you pay for 10 additional users at once at a discount price. For example, if you already pay for 11 users, you can add a user straight away, up until the 20th user.

- Go to Settings -> Account and billing -> Invoices and pay the invoice.

- Go to Settings -> Human Resources and press the "+" button again to enter the pre-paid users.

NB! Users can be added freely during the free trial without any restrictions.

How to change the pricing plan

To change your pricing plan:

- Go to Settings -> Account and billing -> Profile.

- Click Edit and choose your desired plan.

- Save

If you upgrade and are a paying customer, the billing system will create an additional invoice, which you must pay manually once. Your plan will be updated after payment.

For downgrading, please see the next section for additional instructions.

How to downgrade the account

To downgrade from a higher software edition (pricing plan) to a lower one, act as follows:

- Check that your account does not exceed any limits of the chosen lower pricing plan.

- Limits are listed in the MRPeasy Terms and Conditions: /terms/#limits

- Disable all special features which are provided by the higher edition.

- This can be done at Settings -> System settings -> Professional functions and/or Enterprise functions.

- A special feature can be disabled if no special data is created by that function. For example, all serial numbers should be deleted to disable the Serial numbers functionality.

- Change your pricing plan at Settings -> Account and Billing -> Profile.

- In Settings -> Account and Billing, check that you have the desired pricing plan and the next invoice amount is as expected.

How to change the billing cycle

You can change your billing cycle at Settings -> Account and billing -> Profile.

The new billing cycle will take effect after the current billing period ends.

How to change the company name and contact e-mail associated with the account

Contact e-mail

This is the account administrator's email. You can see the Contact email at Settings -> Account and billing -> Profile. Your company's contact email is used to send information from MRPeasy to you.

There are two ways to change it:

- Change the e-mail of the administrator user at Settings -> Human resources -> Users.

- Or, assign some other user as the administrator.

Company name and billing e-mail

You can see and edit the Company and Billing e-mail associated with the account at Settings -> Account and billing -> Profile.

The Company is used on invoices issued by MRPeasy to your company.

- Note that the billing address is entered at Settings -> System settings -> Company details -> Address.

If it is filled, invoices issued by MRPeasy are sent on the Billing e-mail.

How to stop billing

If you want just to stop making payments, you can delete your payment details:

- Go to Settings -> Account and Billing -> Payment data.

- Delete the payment details.

In this case, you can continue using your account until the end of your paid period.

How to delete the account

To delete your account:

- Log in as the administrator.

- Go to Settings -> Account and billing -> Profile.

- Click the Delete my account button.

- Follow the instructions.

NB! Only the administrator can delete the account.

Need Help?

We're here for you!

The Settings -> Support page allows managing support options.

If you get stuck:

- Look into the Quick help for instructions from the User Manual, and the training videos.

- Search the Help Centre for frequently asked questions.

- Write to our support team at Settings -> Support.

- Ask Mr. Peasy, our AI Chatbot, your question.

- You can order personal training hours with our specialists.

- Our Authorized Partners can offer personal implementation services.

- You can allow technical support access to your data to help diagnose specific issues.

Quick Help

For any particular page throughout the program, its explanation can be found by clicking on the Quick Help button in the top right-hand corner.

Support Ticket System

If you get stuck and need help, then please go to Settings -> Support -> Support tickets and create a new support ticket describing the problem in 3 steps:

- Your action – what you did (describe step-by-step, very detailed);

- The expected result;

- The actual output and relevant additional information, e.g., error messages, company ID, username, time, a full screenshot including browser bars, video, etc.

Once you have filed a support ticket, the response will be sent to you in the same place.

Please select the relevant category for your ticket:

- Functionality question – You have a question about existing functionality or availability.

- Development proposal – You have an idea for development.

- Error message – You have received an error message such as "Please contact customer support." There is some technical error with the software.

- Account and billing – You have questions about your account and billing.

- Other - You have other questions.

Mr. Peasy, the AI Chatbot

Mr. Peasy is designed to provide quick and accurate responses to your MRPeasy-related queries, saving you time browsing the manuals. While it does not replace our human support, it’s a handy resource for prompt replies to common questions.

To ask a question from Mr. Peasy, go to Settings -> Support -> Ask Mr. Peasy.

Click the chatbot icon at the page’s bottom, type your question, and press Enter or click Send. Mr. Peasy will promptly respond.

We encourage you to try it out and share your feedback.

Training Hours

You can read about training hours and find the price per hour from Settings -> Support -> Training hours.

Training hours are for learning the functionality of MRPeasy with the help of our specialist.

Disclaimer! Please note that we can train existing MRPeasy functionality but cannot consult you on how to use MRPeasy in your business with your data. We also cannot help you set up integrations with accounting and other external programs.

Implementation Help

If you want a personal approach, someone to guide you and help you set up MRPeasy for your business, please turn to our partners.

Implementation consultations are provided by MRPeasy Authorized Consultants, which are independent consulting companies. Authorized Consultants have their own service and pricing policy. The Authorized Consultants can be found here: /consultants/

Support Access

If you have an issue that you want MRPeasy technical support to investigate and help you resolve, you can allow access to your database so the issue can be investigated.

Access to your database can be allowed at Settings -> Support -> Settings. To revoke access, please ask this via a support ticket.

Only some MRPeasy techs have support access. Support personnel with special access privileges can utilize it when a customer specifically asks for technical help with a clear question. Even then, the data is obfuscated, mostly showing only codes, numbers, and dates (i.e., item descriptions, vendor or customer names, contacts, addresses, workstation names, tasks, operation descriptions, attachments, notes, account names, etc., cannot be seen).

As a policy, MRPeasy employees:

- never access customers' data, except when Support access is allowed, and assistance is explicitly asked to solve a specific issue. Only some tech. support employees have this clearance;

- never review customers' data;

- never input, change, edit, or update customer data in their databases;

- never manually create, edit, or delete accounts/databases. Databases are created automatically with a new account and can be only deleted by the customer or automatically if the account expires;

- never add, edit, or remove users;

- cannot see, add, or edit payment information.

Task Management

Task Management pane can be used to give assignments to team members or to yourself. Task Management enables a simple way to organize work and keep track of assignments. The Tasks pane can be used to send short messages and to keep longer discussions.

The tasks pane can be accessed from the upper right corner by clicking the Tasks icon Tasks.

Tasks can have

- a deadline,

- content with attachments,

- comments from team members.

Usage tips

- Every user can create a new task and assign it to other users.

- When a task is done, mark the checkbox Done.

- When a new task is assigned or an existing task is updated, the Tasks button in the upper right corner blinks.

- A new or updated task is displayed in bold until it is opened.

- Only these tasks are shown, created by the user, or assigned to him/her.

- To remove a task from the pane, the task must be deleted.

- The Tasks pane is updated automatically once per minute.

Access to the Tasks pane

The Tasks pane, located in the upper right corner of the window, can be opened by every user of MRPeasy (except the Internet kiosk user at present).

Dashboard

The Dashboard section of MRPeasy shows the most important metrics about your company's performance.

Tips:

- Clicking on a widget will open the detailed report.

- Add or remove widgets by clicking on the Customize dashboard.

- The order of widgets can be changed by clicking on a widget title and dragging it to a new place.

- Depending on user rights, some widgets may not be visible.

The following widgets are available:

- 7 Days Late Invoices - number of invoices in Unpaid or Paid Partially status and overdue 7 days or more.

- Awaiting inspection - the number of stock lots that must be inspected.

- Available with the Quality Control functionality.

- Cash and cash equivalents - current cash balance based on the general ledger.

- Available with the Standard Accounting module.

- Cash flow - the balance of payments received from customers and payments made to customers from the beginning of the month.

- Cash flow forecast - cash flow forecast for the next two months.

- CO ready to ship - a number of customer orders "Ready for shipment."

- Deliveries on time - the percentage of COs that have been shipped on time since the beginning of the month.

- Deliveries on time % = (The number of on-time shipped COs) / (The number of all considered COs)

- If the shipment date (the date when the Shipment was picked) is earlier or equal to the CO "Delivery date", the CO is considered on time. If there are several shipments, the latest date is used.

- The following COs are considered:

- Orders that should have been delivered this month - with a "Delivery date" from the beginning of this month to today, with any customer order status from "Confirmed" to "Delivered".

- Orders, which are overdue - with a "Delivery date" before this month, with statuses "Confirmed", "Waiting for production", "In production", or "Ready for shipment".

- Orders, which were delivered early - with a "Delivery date" in the future, with statuses "Shipped" or "Delivered".

- Orders without a "Delivery date" are ignored. Delivery dates of individual CO lines are not used.

- Deliveries on time % = (The number of on-time shipped COs) / (The number of all considered COs)

- Expenses - total expenses from the beginning of the month based on the general ledger.

- Available with the Standard Accounting module.

- Expire in 30 days - the number of stock lots that are due to expire in 30 days.

- Available with the Expiry Date functionality.

- Income - total income from the beginning of the month based on the general ledger.

- Available with the Standard Accounting module.

- Items below reorder point - number of stock items whose available quantity is below the minimum desired quantity, below the reorder point level.

- Late CO is the number of customer orders that are confirmed but not shipped and have a past due date.

- Late MO is the number of manufacturing orders that are not finished and have either a due date or a finish date in the past.

- Late PO - number of purchase orders that are not received yet and have an expected date in the past.

- Manufacturing on time - the percentage of MOs that have been made on time from the beginning of the month.

- Manufacturing on time % = (The number of finished MOs, where "Due date" equals to or is after the "Finish date") / (The number of all MOs, for which "Due date" is on or after the 1st of this month)

- This indicator only considers MOs with a "Due date" greater than the beginning of this month. MOs without a "Due date" are ignored.

- MO in progress - number of manufacturing orders that are in progress or paused.

- MO is ready to start. The number of manufacturing orders for which materials are ready in stock.

- OEE – the percentage of overall equipment effectiveness from the beginning of the month.

- Purchases on time - the percentage of PO lines that have been received on time from the beginning of the month.

- Purchases on time % = The number of On-time PO lines / The number of all PO lines

- If the "Received date" of a PO line equals or is before the "Expected date", then it is considered on time.

- The following PO lines are considered:

- Received lines with "Expected date" from the beginning of the month to the current date.

- Not received lines with "Expected date" before the beginning of the month.

- Purchases Orders with statuses "Cancelled" and "RFQ" are ignored.

- Purchases on time % = The number of On-time PO lines / The number of all PO lines

- Rejection rate - the average rejection rate for the current month.

- Available with the Quality Control functionality.

- Sales - the total sum of invoices from the beginning of the month.

- Stock - the total cost of inventory.

- TEEP – the percentage of total effective equipment performance from the beginning of the month.

Settings

The Settings section of MRPeasy gives the ability to:

- modify the settings of your MRPeasy account,

- set your company details and regional settings,

- define work hours, holidays, business days, etc.

- enable additional functionality,

- configure functionality and the user interface,

- access account and billing options,

- access customer support options,

- manage users and departments,

- create and modify different production sites and stocks,

- download database backups and restore backups.

The Settings section has the following sub-sections:

- System settings - contains the settings that customize how the application works.

- Account and billing - where you can manage your subscription.

- Human resources - contains settings regarding users, departments, and workforce planning.

- Production sites/Stocks—This option allows managing multiple physical stocks and/or production sites at different geographical locations. It is available with the Multi-Stock and Production Sites functionality.

- Support - contains conversations with Customer Support (the Support Ticket System), purchasing of training hours and launch packages.

- Database maintenance - contains options for downloading and uploading backups and clearing the database.

Settings - Frequently Asked Questions

Account and billing:

- How to order MRPeasy?

- How to see and pay invoices? (incl. bills for additional users, training, and pricing plan upgrades).

- How to order more users?

- How to change the billing cycle?

- How to choose the Corporate plan?

- How to change your pricing plan?

- How to change the company name and contact e-mail for billing for the account?

- How to delete your account?

Users:

- How to add users to the free trial?

- How to add users to the subscription?

- What is a free user?

- How to access the database logs?

- How to set user access permissions?

- How to hide costs and prices from the user?

- How to enter the hourly wage for labor cost calculations?

- How to enable the internet-kiosk?

- How to give order approval rights?

- What is the lock handler?

- How to limit the IP addresses the user can log in from?

- How to enable two-factor authentication?

- How to change the password?

- How to delete a user?

MRPeasy system settings:

- Where can I define my company details - name, billing address, etc.?

- Where can I define the regional settings - base currency, the first day of the week, time zone, etc.?

- How do I define additional foreign currencies and exchange rates?

- How do I change the default numbering formats for documents?

- Where can I enable Professional package functions?

- Where can I enable Enterprise package functions?

- What are the Software settings, which re-configure functionality?

- What are the Usability settings, which re-configure the user interface?

- How to add custom fields to the MRPeasy database?

- How to define custom write-off types?

- How can I edit PDFs of Purchase Orders, Invoices, etc.?

- How can I manage different warehouses and production sites?

Integrations:

- How to configure integrations?

- How to connect with QuickBooks Online?

- How to connect with Xero?

- How to add attachments in MRPeasy?

- How to display images and CAD files?

- How to connect with Pipedrive?

- How to connect with Shopify?

- How to connect with Magento?

- Where is the API documentation? (API usage is available only on Unlimited plan)

MRPeasy support:

- How can I reach MRPeasy customer support?

- How to access the Quick Help?

- How can I order personal training?

- How can I get personal implementation help?

- How can I allow/deny technical support access to my database?

Database maintenance:

- How can I download a backup of the database?

- How can I restore my database from a backup?

- How can I clear the database?

Jump to other FAQs:

System Settings

The Settings -> System settings section contains the settings which customize how the application works.

- Regional Settings - customize how the information is displayed according to local specifics, e.g. timezone, the first day of the week, base currency, etc.;

- Company Details - enter the information about your company, which will be displayed in the documents sent to your customers and vendors;

- Numeration Formats - set the numeration formats based on which document numbers are generated in MRPeasy;

- Work Hours - define the work hours for each day;

- Holidays - enter the dates of holidays when no work will take place;

- Professional Functions - enable or disable the Professional functions;

- Enterprise Functions - enable or disable the Enterprise functions;

- Software Settings - set preferences for the software interface;

- Usability Settings - set preferences for your personal interface;

- Notifications - set personal e-mail notifications;

- Additional Currencies - define additional currencies and their exchange rates;

- Allowed IPs - define IP addresses that are allowed to sign in to your account at MRPeasy;

- Integrations - configure integrations of MRPeasy with other software;

- PDF editor - customize the layouts of PDF documents;

- Label editor - customize labels;

- E-mail editor - customize subjects and texts of e-mails that can be sent to your customers and suppliers;

- Internet-kiosk editor - customize the information that workers can see for production reporting;

- Custom fields - add custom fields to your MRPeasy database;

- Write-off types - define custom write-off codes for manual write-offs;

- Customer Statuses - rename default customer statuses in CRM.

Regional Settings

The Settings -> System settings -> Regional settings page allows you to customize how information is displayed in MRPeasy according to your local specifics.

Demo video: Setting up business details, working hours, PDF editor.

The following information can be defined on this page:

- Time zone - time zone you are in by continent and city, e.g., Europe/London.

- Date Format - how dates are displayed, e.g., dd.mm.yyyy, mm/dd/yy, etc.

- First day of the week - which day the calendars display as the first day of the week.

- Decimal separator - choose whether the decimal separator is a comma or a dot.

- Thousands separator - choose whether the thousands separator is a comma, a dot, or a space.

- CSV separator - choose whether the field separator in CSV files is a comma or a semicolon (when exported).

- Currency sign - your base currency. Enter the default currency sign, e.g., USD, EUR, GBP, AUD, etc. You can use also signs $, €, £, however, they will not work for automatic update of the currency rate, if you will use it.

Important! Changing the base currency sign in a live database will not affect financial values or the recalculation of documents and exchange rates; only the sign will be changed. - Currency format - how prices and costs are displayed, e.g. as 100€ or €100.

- Generic name of an undefined place in stock - name of the default storage location in Stock; by default, it is "General".

Company Details

The Settings -> System settings -> Company details page allows you to enter information about your company, which will be displayed in the documents created by MRPeasy.

Demo video: Setting up business details, working hours, PDF editor.

The following information can be defined on this page:

- Company name - the name of your company. This information is printed on invoices, quotations, purchase orders, etc., and invoices from MRPeasy.

- Contact details - your company's address is a free text. This information is displayed on invoices, quotations, purchase orders, etc., and invoices from MRPeasy.

- E-mail - enter your company's general e-mail address.

- Website - the URL of your company's website.

- Phone - your company's phone number.

- Reg. no. - your company's registration number.

- VAT number—your company's VAT number if you are from the EU and have a valid VAT number. This eliminates 22% of the VAT from MRPeasy's invoice to you.

- VAT rate / Tax rate - your VAT, GST, or Sales Tax rate. This will be added to the Invoices and Quotations you create as the default tax rate.

- Payment details—Please enter your payment details as free text. This information will be added to the Invoices and Quotations you create.

Holidays

The Settings -> System settings -> Holidays page allows entering the dates of holidays when no work takes place.

Demo video: Setting up business details, working hours, PDF editor.

- No manufacturing operations will be scheduled for these days.

- Custom holidays can be configured for each workstation group at Production Planning -> Workstation Groups -> Details of a Workstation Group.

Numbering Formats

The Settings -> System settings -> Numbering formats page allows you to set the numeration formats and current sequence numbers based on which document numbers are generated in MRPeasy.

Each time a new document is created, the sequence number increases by one.

Here are the default formats for each document:

| Customer orders | CO00001 |

| Customers | CU00001 |

| Invoices | I00001 |

| Pro-forma invoices | PI00001 |

| Quotations | Q00001 |

| Order confirmations | OC00001 |

| Pricelists | PL00001 |

| Manufacturing orders | MO00001 |

| Workstations | C00001 |

| Workstation groups | WCT00001 |

| BOM | BO00001 |

| Routings | R00001 |

| Items | A00001 |

| Lots | L00001 |

| Shipments | S00001 |

| Transfer orders | TO00001 |

| Product groups | AG00001 |

| Relations | RE00001 |

| Bookings and Write-offs | WO00001 |

| Purchase orders | PO00001 |

| Vendors | V00001 |

| Customer Returns (RMAs) | RMA00001 |

| Service Orders | SO00001 |

| Procurement forecasts | PF00001 |

Working Hours

The Settings -> System settings -> Working hours page allows defining the work hours for each calendar day.

Demo video: Setting up business details, working hours, PDF editor.

- The work hours define how many hours a day workstations can be loaded.

- The default hours are Monday through Friday, 08:00 – 17:00.

- 24-hour workdays (e.g., three 8-hour shifts) must be defined as 00:00 – 23:59.

- Each day with work hours is considered a business day (material lead times are defined in business days for higher accuracy).

- Custom work hours can be configured for each workstation group at Production Planning -> Workstation Groups -> details of a workstation group.

- The operation time tracker automatically suspends work that is not completed or paused at the end of the working day. This is done from 1 a.m. to 3 a.m.

Professional Functions

You can turn on the Professional package functions in the Settings -> System settings -> Professional functions section.

The additional functions available in the Professional package are:

- B2B Customer Portal - a web store that allows your customers to order products directly from you;

- Co-product BOM - add side-products (side-products, scrap, waste) to BOM, which can also be retrieved to stock from the same Manufacturing Order;

- Custom fields (always on) - add custom fields to the database;

- Disassembly BOM - ability to disassemble a product into parts.

- Expiry date - track expiry dates of stock lots;

- Fixed Quantity - fix a part quantity in a BOM irrelevant to the order quantity;

- Matrix BOM - define parametrical products, which have many variations;

- Non-inventory items - create items that are not tracked in inventory;

- Overlap and special sequences of production operations - subsequent operations can overlap; several chains of operations that can diverge/converge can take place at one time for one product;

- Parallel execution of production operations - an operation can be divided into smaller parallel operations among all available workstations of the same group;

- Piece payment - workers can be paid per piece; time payment can be disabled;

- Quality Control - items can be subject to quality control before being taken into stock (both procured and manufactured);

- Serial numbers - individual pieces of any item can be tracked by its serial numbers;

- Subcontracting - using subcontracted processes in production, free issuing stock to subcontractors;

- Tiered pricing - define different sales price sheets and pricing tiers per order quantity;

- Unscheduled manufacturing orders - the ability to remove planned manufacturing orders from the production schedule.

B2B Customer Portal

The B2B Customer Portal functionality provides a web store that your customers can use to place orders, track order progress, and access invoices. It is deeply connected with your MRPeasy CRM. You can choose which customers receive access and control which products each can see and buy.

The Customer Portal empowers your customers to:

- Place orders.

- Monitor order statuses, dates, and tracking numbers.

- Access their invoices.

Jump to:

- Demo video: Customer Portal.

- Setting up.

- Using the Customer Portal.

Setting up the Customer Portal

Enabling the B2B Customer Portal functionality

The B2B Customer Portal can be enabled at Settings -> System Settings -> Professional Functions -> B2B Customer Portal.

The setting Auto-creation of variations of the Matrix BOM functionality should be switched off for compatibility with the Customer Portal.

Inviting customers or revoking their access

To invite a customer to the Customer Portal:

- Navigate to CRM -> Customers -> Customer details.

- Press the Invite to Portal button.

- The system will generate a pre-filled email for your customer with a unique link for logging into the Customer Portal. Send this email to your customer.

- The customer can access the portal by opening their unique link.

To revoke a customer's access from the Customer Portal:

- Navigate to CRM -> Customers -> Customer details.

- Press the Revoke customer from Portal button. This will render the previously shared unique link invalid.

Product visibility in the Customer Portal

The list of products a customer can see and order is determined based on the pricelist assigned to the customer:

- If a pricelist is assigned to the customer (part of Tiered Pricing functionality), only the products in the pricelist are visible.

- If no pricelist is assigned to the customer, all items with a selling price defined in the item’s details (the default pricelist) are visible.

Customer’s currency

All prices are displayed in the currency assigned to the customer at CRM -> Customers -> Customer details.

If selling prices are defined in a different currency, these will be converted to the customer's currency using the exchange rate specified at Settings -> System Settings -> Additional Currencies.

Using the Customer Portal

Overview of the Customer Portal

In the portal, customers have access to the following pages:

- Catalog - where customers can add products to the cart.

- Cart - where customers can review and place their orders.

- My orders - where customers get a complete overview of all their orders and can access their details.

- Order details - where customers can see the order details and initiate a reorder.

- My invoices - where customers get a complete overview of their invoices and can access their details.

- Invoice details - where customers can see the invoice details and download the PDF copy.

Ordering through the Customer Portal

- Adding products to the cart. Upon logging in, customers are directed to the Catalog page. Here, customers can add products to the cart.

- Reviewing the cart. Next, on the Cart page (accessible from the top right), customers can review the order and make necessary changes.

- Selecting a shipping address. On the Cart page, one shipping address can be selected from the addresses defined in the customer’s details in the MRPeasy CRM. If the customer does not have a saved address, the option "Pickup at Vendor’s location" will be used.

- Placing an order. The order is confirmed and placed upon clicking the Create Order button on the Cart page.

- Invoicing and payments. Once an invoice for the order is created in the MRPeasy CRM, it will be accessible from the portal, along with information about payments.

- Shipping. Once a shipment for the order is created in the MRPeasy CRM, it will be visible in the portal.

- Reordering. When you click Order again at Customer Portal -> My Orders -> Order details, the Cart page opens and is pre-filled with the same items.

Processing portal orders in the MRPeasy CRM

When an order is placed through the Customer Portal:

- It will appear in a Confirmed status at CRM -> Customer Orders.

- A new task will be to notify the customer's account manager of the order.

Subsequently, such orders should be processed as any other orders in the MRPeasy CRM.

Some things to note:

- Invoices are not created automatically.

- The estimated shipping date will be displayed in the portal when the CO delivery date is filled out.

- Changes to CO statuses are mirrored in the portal.

CO statuses in MRPeasy CRM and Customer Portal

The Customer Portal displays only customer orders in the following statuses:

|

CO status in MRPeasy CRM |

CO status in Customer Portal |

|

Confirmed |

Ordered |

|

Waiting for production |

Processing |

|

In production |

Processing |

|

Ready for shipment |

Ready for shipment |

|

Shipped |

Shipped |

|

Delivered |

Shipped |

COs with other statuses are not shown in the Customer Portal.

Co-Product BOM

The Co-product BOM functionality allows for producing additional products due to one manufacturing order.

This allows line workers to report the number of co-products, side products, rejected products, or scrap.

This functionality can be enabled at Settings -> System settings -> Professional functions -> Co-product BOM.

Jump to:

- Demo video: Co-Product BOM.

- Configuring co-products.

- Reporting co-products.

- Cost allocation to co-products.

Configuring additional products

Co-products must be previously configured in the BOM of the main product before these can be reported.

To set up additional products:

- At Stock -> Items, create the articles for additional products, such as waste or scrap.

- Open the BOM of your product, where these items will be produced as additional side-products.

- Add the possible additional products in the section Additional product.

- Set the percentage of total MO costs allocated to co-products. If undefined, the cost is 0.

Reporting co-products, adding additional products to stock

Additional products can be reported in several places:

- Co-products are added to stock when these are reported by workers in My production plan or in the Internet-kiosk when they pause or finish a production operation. The software will ask for the quantities of products and additional products that have been processed.

- Also, co-products can be reported in the manufacturing operation details. Read: How to edit operations in a Manufacturing Order?

The cost of the additional products

It is possible to divide the costs of a manufacturing order between the main product and the co-products of the main product.

To do so, the percentage of costs that are allocated to co-products must be set in the product's BOM details.

Note that:

- A cost allocation percentage is set per unit.

- If the percentage is undefined, the cost is 0.

For example, with one co-product, if 20% of costs are allocated to a co-product, then:

- 100% - 20% = 80% of costs will be allocated to the main product (percentages must add up to 100%).

- One unit of co-product will be allocated 4 times (80/20) fewer costs than one unit of the main product, i.e., a co-product cost will be 1/4th of the main product.

- If the total MO cost is $1000, 24 main products and 4 co-products are made, then costs will be allocated as follows:

| Total MO cost: | A = Direct materials + Direct labor + Overhead = | $ 1000 |

| Cost of 24 main products: | B = 24 x 80% x A / (24 x 80% + 4 x 20%) = | $ 960 |

| Cost of 4 co-products: | C = 4 x 20% x A / (24 x 80% + 4 x 20%) = | $ 40 |

| Cost of 1 main product: | D = B / 24 = | $ 40 |

| Cost of 1 co-product: | E = C / 4 = | $ 10 |

How to find the cost allocation percentage for a co-product

The cost of a co-product is a business decision. Standard costs for co-products and main products should be found, or cost ratios should be set. Only then it is possible to calculate the cost allocation percentage to use in the software.

- General formula: Cost percentage of co-product A = (Cost per unit of co-product A) / (Sum of all unit costs of co- and main products)

- In case of 1 co-product: X = E / (D + E)

X - the cost allocation percentage for the co-product. The unknown variable.

D - the cost per unit of the main product.

E - the cost per unit of the co-product.

If the costs are $40 and $10, we find the cost allocation percentage: X = 10 / (10 + 40) = 20%

If you have more co-products, then the same approach can be used for all.

For example, 3 co-products:

| Product | Standard cost per unit | Calculation | Percentage | Comment |

| Main product | 10 | 10 / 16 = | 62.5% | This can be calculated for a check, to verify that the sum of cost allocation percentages adds up to 100%. This is not entered into the software |

| By-product 1 | 1 | 1 / 16 = | 6.25% | |

| By-product 2 | 2 | 2 / 16 = | 12.5% | |

| By-product 3 | 3 | 3 / 16 = | 18.75% | |

| Sum: | 16 | 100% |

If there is no standard cost, but ratios or weights are in place instead, then the result can be found with the exact same approach, as in the above table. E.g. by-product 1 cost is 1/10th of the main product, by-product 2 cost is 2/10ths, by-product 3 cost is 3/10ths, etc.

Co-products in a multi-level MO

Attention! In multi-level MO, co-product BOM cost allocation can only be used at the first level (the main product of the MO).

- The creation of co-products of sub-assemblies can be reported during the reporting of their operations.

- The co-products of sub-assemblies will have a 0 cost, regardless of cost allocation percentage.

Custom Fields

Starting from the Professional edition of MRPeasy, the Settings -> System settings -> Custom fields page allows you to configure additional database fields in your MRPeasy database.

Demo video: "Custom fields" functionality.

- Max. 30 custom fields can be added.

- Custom fields provide additional opportunities for searching and sorting but not for calculations.

- Custom fields are hidden by default in the tables; click Choose columns to make them visible.

- The custom field can be a free text, number, date, or a drop-down with pre-defined options.

- A custom field can be marked "Required," so the user must fill the field.

- For drop-down type custom fields, it is possible to add multi-line text for PDFs as one choice by using "\n" as the line-break character (e.g., "Line1\nLine2\nLine 3" for three separate lines within one option).

- In the MRPeasy user interface, you will still see the text as a single line with line-break characters ("Line1\nLine2\nLine 3"); the text will only be on separate lines on generated PDFs.

Custom fields can be added to the following objects:

| Object | Comments |

| Customer orders | |

| Customer returns (RMAs) | |

| Customers | |

| Invoice | |

| Manufacturing orders | Custom fields for MOs can be shown in My Production Plan. |

| Procurement invoices | |

| Purchase orders | |

| Purchase terms | |

| Shipments | |

| Stock items | Custom fields for Stock Items can be added to several PDFs. By editing the layouts with the PDF editor, these fields can be included in other documents besides invoices and POs. |

| Stock lots | Custom fields for Stock Lots can be "Persistent." This means that custom field values will be transferred to a new stock lot, created automatically due to a transfer order or rejection during an inspection. |

| Transfer orders | |

| Vendors |

Disassembly BOM

The Disassembly BOM functionality allows disassembling (cutting) a product into parts. The cost of the product is divided between new parts.

This functionality can be enabled at Settings -> System settings -> Professional functions -> Disassembly BOM.

Jump to:

- Demo video: Disassembly BOM.

- Configuring disassembly BOM.

- Cost allocation percentage calculation.

- Disassembling a product.

Configuring disassembly BOM

- When creating a BOM, choose the "This is disassembly BOM" option.

- Enter the parts into which the product can be disassembled.

- For each part, enter a quantity and a cost percentage. The sum of the cost percentages must be 100%. See the example below.

Connecting the disassembly BOM with routings:

- The routing can be selected in the disassembly BOM details. In this case, the disassembly manufacturing order will contain operations.

- If no routing is selected in the disassembly BOM details, then the manufacturing order will contain no operations and will be considered as an un-kitting MO.

- Routing can be linked to a normal BOM or a disassembly BOM, but not both.

Disassembly cost calculation example

For example, we wish to disassemble a table into its parts: 1 table top and 4 table legs. We have already figured out the expected standard costs (or cost ratios) for the parts.

The disassembly cost percentages for parts are calculated as follows:

| Part | Standard cost (or cost ratio) of the part | Cost percentage | Comment | |

| Table top | $ 7 | 7 / 10 = | 70% | Note that the quantity of the part in the Disassembly BOM does not play any role in calculating the cost allocation percentage. |

| Table leg | $ 3 | 3 / 10 = | 30% | |

| Total: | $ 10 | 100% | ||

And the disassembly BOM will look as follows:

| Part | Quantity | Cost percentage |

| Table top | 1 | 70% |

| Table leg | 4 | 30% |

If we disassemble the product, when the Disassembly MO has a cost of $19 per piece, we get the following result:

| Total MO cost: | A = Direct materials + Direct labor + Overhead = | $ 19 | |

| Cost of 1 table top: | B = 1 x 70% x A / (1 x 70% + 4 x 30%) = | $ 7 | This correctly equals the expected standard cost in our previous calculation. |

| Cost of 4 table legs: | C = 4 x 30% x A / (1 x 70% + 4 x 30%) = | $ 12 | |

| Cost of 1 table leg: | C / 4 = | $ 3 | This correctly equals the expected standard cost in our previous calculation. |

Disassembling a product

To disassemble a product, create a manufacturing order and select a disassembly BOM.

If the manufacturing order contains operations, then please complete operations and report the results. Parts are added to the stock when an operation is paused or finished.

If a manufacturing order contains no operations, it is automatically executed after the required quantity of products has been ordered and received. Parts are added to the stock automatically.

Expiry Date

The Expiry date functionality allows tracking expiry dates and setting shelf life for the stock lots of parts, ingredients, and finished products.

Please note that the Expiry Date functionality requires Tracing to be enabled.

Jump to:

- Demo video: Expiry date.

- Enabling Expiry dates functionality.

- Automatic calculation of the expiry date.

- Manually setting the expiry date.

- Using expired goods.

- The expiry date of kits/bundles.

- Transferring items with expiry dates.

Enabling Expiry dates functionality

This functionality can be enabled at Settings -> System settings -> Professional functions -> Expiry dates.

When it is enabled, then:

- The "Expiry date" field is available for stock lots (at Stock -> Stock lots) and can be manually updated.

- The default "Shelf life" in days can be set for items on the item's details page (at Stock -> Items).

- Expired items are ignored when the software automatically creates bookings.

- Automatically created bookings for materials and products are based on FEFO (First Expired, First Out), i.e., items that expire earlier are used before items that expire later.

- The "Expire in 30 days" indicator will become available on the Dashboard. It will provide a report of all lots that expire in 30 days.

Automatic calculation of expiry date

When purchase orders or manufacturing orders are created, the software tries to automatically estimate the expiry date by adding the item's Shelf life to the date when this product is received in the stock, i.e., Expiry date = Available date + Shelf life.

Manually setting the Expiry date

The Expiry date can be set for each stock lot in its details at Stock -> Stock lots.

If a stock lot does not expire, leave this field empty.

Using expired goods

The software does not automatically book expired items, but it is possible to manually book them, use them in production, or ship them to customers.

If a product has expired and is going to be shipped, the software will issue a warning to the user when picking it up for shipment.

Expiry date of kits/bundles

The expiry date of a kit is calculated automatically and is equal to the earliest expiry date of the products in that kit. To change the kit's expiration date, please change the expiration date of the products contained in it.

Transfer orders and expiry dates

When making a transfer order between sites:

- If the source stock lot has an expiration date, the date will be copied to the target stock lot.

- Changing the expiry date in the initial stock lot also updates the expiration date in the target stock lot.

Fixed Quantity

The Fixed quantity functionality allows a component's quantity to be independent of the number of products in the manufacturing order. While normally the quantities on a BOM are multiplied by the number of items on the MO to calculate the required materials, the fixed quantity number will not be multiplied, it's fixed.

This functionality can be enabled at Settings -> System settings -> Professional functions -> Fixed quantity.

When the Fixed quantity option is turned ON, then:

- The Fixed quantity column becomes available on Bills of Materials.

- If some part is used a fixed amount, irrelevant to the order quantity, it can be entered in the Fixed Quantity column on the BOM (e.g. a user manual, gloves, tools boxed with the products, etc.)

- A material's quantity on a MO = MO's number of products x Quantity in the BOM + Fixed quantity in the BOM.

Non-inventory items

The Non-inventory items functionality allows users to use non-inventory items, i.e., turn off inventory tracking for these items.

Examples of non-inventory items include office furniture and supplies, cleaning supplies, equipment rentals, and internet or travel expenses. They can also include small or incidental items necessary for daily operations that do not fit into a specific inventory category.

We do not recommend using non-inventory items for services because you will not be able to collect statistics on their sales. Please read what we recommend in this FAQ section article.

- Non-inventory items can only be used in Purchase Orders, Customer Orders, and Invoices (they can be bought and sold, such as office equipment).

- Non-inventory items cannot be used in BOMs, Manufacturing Orders, or Shipments.

- These items are not part of inventory or inventory management (they do not have stock lots, bookings, etc.) and aren't visible in Stock -> Inventory.

This functionality can be enabled at Settings -> System settings -> Professional functions -> Non-inventory items.

When the functionality is enabled, then:

- The setting This is an inventory item (Yes/No) will become available when creating a new article at Stock -> Items. This setting defaults to "Yes" (the entered item is a stock item).

- Once the item has been saved, this setting cannot be changed. An inventory item cannot be converted to non-inventory and vice versa.

Jump to:

- Demo video: Non-Inventory Items

- Using non-inventory items in Customer Orders

- Expense items for procured services

- Charging for services

Using non-inventory items in Customer Orders

If the Professional function “Non-inventory items” is enabled, non-inventory items can be added to customer orders.

You can use these for services without direct cost (for example, an additional guarantee).

When the software updates the customer order’s Status and Part status, non-inventory items are ignored. If a customer order contains only non-inventory items, it is possible to select any CO status manually.

If the item has a cost (for example, shipping that you order from a vendor of yours), please create a regular item. This allows linking customer orders with purchase orders and thus allocating costs towards particular customer orders. To separate these items from inventory items, please create a separate product group.

Expense items in MRPeasy Accounting

If you pay for services or non-inventory items, which should be expensed immediately, it is possible to:

- Set an expense account as the default posting account for non-inventory items.

- Go to Accounting -> Chart of accounts.

- Edit the expense account.

- Select it as a default account for "non-inventory items."

- Or, set a custom account for the product group containing the non-inventory items.

Posting date

If you have been billed for your non-inventory item now, but it is actually last month's expense, then enter the invoice date from last month for your correct bookkeeping.

See also: Automatic accounting transactions.

Overlap and Special Sequences of Manufacturing Operations

The Overlap and special sequences of manufacturing operations functionality allow:

- Overlapping consecutive production operations in batch production.

- Configuring special (non-linear) operation sequences, e.g., parallel chains of operations, in a single Routing,

This function can be enabled at Settings -> System settings -> Professional functions -> Overlap and special sequences of manufacturing operations.

When this function is enabled:

- The Overlap column becomes available in the Routing Details with a checkbox (Yes/No) on every operations line. The overlap quantity, which is how many products must be finished in the previous operation before starting, can be defined if selected.

- The Sequence columns are added to the Routing Details page, where each operation's preceding operations can be defined.

Jump to:

- What is Routing?

- What is overlapping? How to set up an overlap of operations?

- What is a special sequence? How to set up special sequences of operations?

- Demo video

Overlap of operations

The Overlap setting in the Routings details means that consecutive operations in the same Manufacturing Orders can overlap, i.e., the next operation could start before the previous finishes when batch processing products. For example, when 10 table assemblies are finished (of 100 total), the next operation, painting, can start.

For configuring Overlap for an operation:

- Open the Routing of the product.

- Tick the Overlap checkbox on the operation line, which can start before the previous operation is finished. (The overlap setting cannot be applied to the 1st operation.)

- Enter the number of products that need to be processed in the previous step before this operation can start.

If this function is used:

- The operation is divided into (many) smaller operations, each with an "Overlap" quantity (or greater).

- For best results, it is recommended that multiplication "Cycle time" * "Overlap" = 1 minute or more, and "Overlap" equals to or is a multiple of "Quantity".

- If "Overlap" quantity * "Cycle time" < 1 minute, then the software will round this up to 1 minute, which is the minimum scheduling time unit in MRPeasy.

- For example, if "Cycle time = 0.05 min" and "Quantity = 1", then 20 units are processed in 1 minute, and if the "Overlap = 1", MRPeasy will treat each separate 0.05-minute operation as a 1-minute operation (which means it would take 20 minutes for 20 units).

To resolve this, the parameters should be defined along the following lines:

- "Cycle time = 1 min"

- "Quantity = 1 / 0.05 = 20"

- "Overlap = a multiple of "Quantity" = 20 or more"

Take note:

- In practice, this kind of overlapping is easily applicable in a balanced production line (i.e., different steps take equal amounts of time). However, overlapping scheduling is harder to apply to an unbalanced production line because it's more difficult to avoid queues or idling, which requires careful planning.

- This setting only affects the scheduling of the operations, allowing the MO to be scheduled in a more compact way if workstations are available.

- This setting does not forbid reporting the start of the next operation before the previous one is reported as finished.

Special sequences of operations

The Sequence setting in the Routing details allows defining parallel and converging/diverging chains of operations. While by default the sequence of operations in routing is linear, this allows configuring a custom order of production operations. E.g., when two independent operations start in parallel, and the third operation can only start before these two have finished.

For configuring a special sequence of operations:

- Open the Routing of a product.

- The first operation's Sequence value must be chosen as 0.

- Set the Sequence values for the operations which can start immediately as 0.

- For every other operation, in the operations' Sequence choice, choose the number of operations that need to be finished before this operation can start. (Press the Ctrl or Shift key, or click-hold the left mouse button to select multiple values.)

Example:

| Operation # | Operation | Sequence |

| 1 | 1st operation of the first sequence | 0 |

| 2 | 1st operation of the second sequence | 0 |

| 3 | 2nd operation of the first sequence | 1 |

| 4 | 2nd operation of the second sequence | 2 |

| 5 | Final operation | 3,4 |

The number in the Sequence field indicates after which operations this operation can start. The operation's ID number is displayed at the beginning of its line.

Demo video: How to configure complex sequences of operations - parallel, converging, or diverging chains of operations.

Parallel Execution of Production Operations

This parallel execution of production operations functionality allows for the division of one operation into smaller pieces to be processed in parallel on several workstations simultaneously. It's possible to define in the Routing that an operation is divided between all workstations of the same group.

This functionality can be enabled at Settings -> System settings -> Professional functions -> Parallel execution of production operations

When this function is turned On:

- The Parallelize column becomes available in the Routing Details with a checkbox (Yes/No) on every operations line.

- If the Parallelize option is enabled for an operation, it will be divided into smaller parallel operations among all available workstations of the same group.

- Then approximately: Operation duration = Cycle time x Quantity / Number of workstations*

* The actual planned duration may differ due to workstation productivity and availability differences.

Jump to: